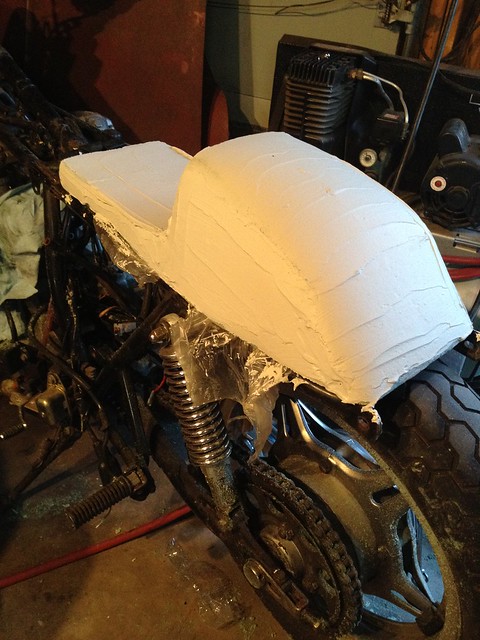

From the foam emerged a seat shape

Once I finished with the green foam's shape I moved on to the detail. I used sheetrock mud to build the final shape.

This was a slow process to form the curves symmetrically and smooth.

Once the shape was as close as possible it was time to fiberglass

I started by laying fiberglass mat down over the drop cloth

Once I laid down enough fiberglass mat down to build a good solid initial shape, it was time to remove it and start building up the backside of the mold.

I cut the edges off and got prepped to build up the underside of the mold

I built the sides up as well as the cowl and obviously the part where your ass is planted.

During this time I fabricated some crude but adequate mounts to fiberglass into the lower portion of the seat and started test fitting and cutting.

I also built a nice rear mount of 1" box steel and welded some nuts on. This mounted to the rear portion of the frame tubes.

During this time I shaved the stock triple clamp and cleaned up the frame so I could add the rearset mounts and front seat mount.

And there you have it, the seat has bondo on it and its mounted up. I did knee cutaways in the gas tank a while back and finished it up and did the bondo'ing on it as well at this time. The body is coming together but still far from done, stay tuned

No comments:

Post a Comment