Saturday, August 25, 2012

Hey! Its Saturday, here is an updated picture of the CB!

So I felt the stance was a little off previously. The rear end sat just too low with the 11.5" shocks so I tossed on some 13"ers we had floating around storage and I have to say, it drastically improved every aspect of this bike. Previously with the rear being a hair lower than the front it caused the rake angle to decrease and cause all kinds of undesirable steering, braking and dampening issues. The forks currently are CB550 forks with progressive springs, heavier fork oil and shims to increase rates. It rode decently but to be honest, the steering has suffered tremendously from the lowering of the bike. By raising the rear of the bike it increased the rake angle which improved the stability of the bike greatly. The bike no longer has steering wobbles or very slow turning response. The bike carves corners better and even responds better to bumps in the road due to increased preload in the front suspension. The rates of the rear are not ideal currently, and are a touch stiff which is fine for now, all things will get tweaked over time and improved. The neck bearings will get updated very soon as well.

My plans for the front end of this bike is to fit a better rotor/caliper setup, modern brake master and braided lines and the a fore mentioned bearing replacement.

Bring back the spokes!

I had to own Mag wheels to realize I don't like Mag wheels.... so here we are going back to that beautiful style that classic bike's embody. 40 spokes of vintage goodness will be laced to a new rim and a squeeky clean hub!

The old rear rim was tossed to make way for a Harley 4.25" DNA rim!

I ordered up a Shinko SR741 in a 140mm width and dropped off the spoke kit from Buchanan, hub and rim to be laced by a local shop. I would try my hand at lacing the wheel myself but in all honesty, I would rather the peace of mind of knowing it was done perfectly.

I started polishing the hub up to a dull shine, don't want it obnoxiously shiney. Trust me, too much chrome is definitely a bad thing.

I also took and made a muffler/tail pipe from a small bullet style muffler we had floating around the garage.

I took the muffler and welded some 3.5" pipe over it. I cut a slit down the center of the exhaust pipe so it would fit snuggly around the muffler and welded the rear portion of it together:

Once that was in place I took more 3.5" and pushed it inside the cut/stretched pipe/muffler piece. I did this to seal up that seam of 1" that was open.

I welded all the pieces together and inside the pipe to make sure nothing will rattle or come loose. I also welded the tip of the pipe to hide that it was multiple pieces, turned out kind of cool.

With all of that done I welded the pipe to the factory 4-1 header and mounted the tire and brakes back on. The exhaust sounds decent, it didn't really quiet it down too much but it does a little. I will probably add some kind of baffling to the inside of the pipe or possibly just build my own header, not sure yet.

Here is what the finished product looks like:

It all has turned out so well thus far, I am looking forward to getting paint on the bike and ditching the god-awful Keihin carbs for the Mikunis I have in the garage. I will be fabricating some intakes and converting over sometime in the near future as well as completely rewiring the bike with Weatherpack connectors and a sexy new fuse/power block setup. Stay tuned!

The old rear rim was tossed to make way for a Harley 4.25" DNA rim!

I ordered up a Shinko SR741 in a 140mm width and dropped off the spoke kit from Buchanan, hub and rim to be laced by a local shop. I would try my hand at lacing the wheel myself but in all honesty, I would rather the peace of mind of knowing it was done perfectly.

I started polishing the hub up to a dull shine, don't want it obnoxiously shiney. Trust me, too much chrome is definitely a bad thing.

I also took and made a muffler/tail pipe from a small bullet style muffler we had floating around the garage.

I took the muffler and welded some 3.5" pipe over it. I cut a slit down the center of the exhaust pipe so it would fit snuggly around the muffler and welded the rear portion of it together:

Once that was in place I took more 3.5" and pushed it inside the cut/stretched pipe/muffler piece. I did this to seal up that seam of 1" that was open.

I welded all the pieces together and inside the pipe to make sure nothing will rattle or come loose. I also welded the tip of the pipe to hide that it was multiple pieces, turned out kind of cool.

With all of that done I welded the pipe to the factory 4-1 header and mounted the tire and brakes back on. The exhaust sounds decent, it didn't really quiet it down too much but it does a little. I will probably add some kind of baffling to the inside of the pipe or possibly just build my own header, not sure yet.

Here is what the finished product looks like:

It all has turned out so well thus far, I am looking forward to getting paint on the bike and ditching the god-awful Keihin carbs for the Mikunis I have in the garage. I will be fabricating some intakes and converting over sometime in the near future as well as completely rewiring the bike with Weatherpack connectors and a sexy new fuse/power block setup. Stay tuned!

Wednesday, August 22, 2012

Time to build the seat

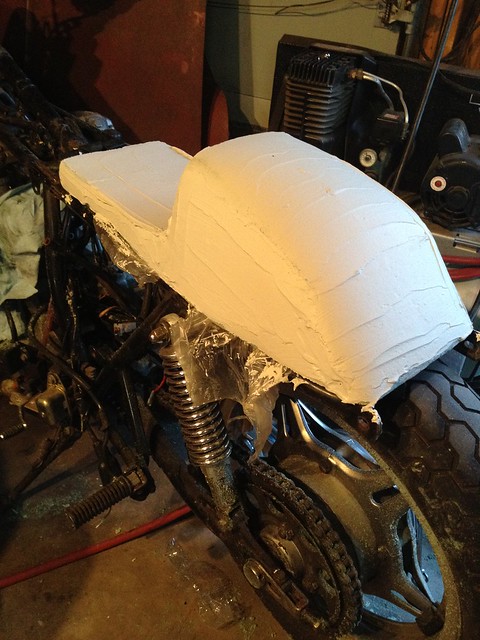

I purchased some green foam and glued them together on top of the bike frame.

From the foam emerged a seat shape

Once I finished with the green foam's shape I moved on to the detail. I used sheetrock mud to build the final shape.

This was a slow process to form the curves symmetrically and smooth.

Once the shape was as close as possible it was time to fiberglass

I started by laying fiberglass mat down over the drop cloth

Once I laid down enough fiberglass mat down to build a good solid initial shape, it was time to remove it and start building up the backside of the mold.

I cut the edges off and got prepped to build up the underside of the mold

I built the sides up as well as the cowl and obviously the part where your ass is planted.

During this time I fabricated some crude but adequate mounts to fiberglass into the lower portion of the seat and started test fitting and cutting.

I also built a nice rear mount of 1" box steel and welded some nuts on. This mounted to the rear portion of the frame tubes.

During this time I shaved the stock triple clamp and cleaned up the frame so I could add the rearset mounts and front seat mount.

And there you have it, the seat has bondo on it and its mounted up. I did knee cutaways in the gas tank a while back and finished it up and did the bondo'ing on it as well at this time. The body is coming together but still far from done, stay tuned

From the foam emerged a seat shape

Once I finished with the green foam's shape I moved on to the detail. I used sheetrock mud to build the final shape.

This was a slow process to form the curves symmetrically and smooth.

Once the shape was as close as possible it was time to fiberglass

I started by laying fiberglass mat down over the drop cloth

Once I laid down enough fiberglass mat down to build a good solid initial shape, it was time to remove it and start building up the backside of the mold.

I cut the edges off and got prepped to build up the underside of the mold

I built the sides up as well as the cowl and obviously the part where your ass is planted.

During this time I fabricated some crude but adequate mounts to fiberglass into the lower portion of the seat and started test fitting and cutting.

I also built a nice rear mount of 1" box steel and welded some nuts on. This mounted to the rear portion of the frame tubes.

During this time I shaved the stock triple clamp and cleaned up the frame so I could add the rearset mounts and front seat mount.

And there you have it, the seat has bondo on it and its mounted up. I did knee cutaways in the gas tank a while back and finished it up and did the bondo'ing on it as well at this time. The body is coming together but still far from done, stay tuned

Sunday, May 13, 2012

Where it all began.

I purchased a 1976 Honda CB750F for a whopping $450 from a local fella here in northern Minnesota. It was a mess, the electrics were a clusterfuck, the carbs were gunked and had a torpedo for a muffler.

I started by stripping the bike down a bit and repairing the electronics and cleaning the carbs. A previous owner chopped the fuse block out and used wire nuts.

I wired in a factory fuse block from another CB:

Time to scrub the carbs:

Once I got the bike to a rideable state by removing the awful muffler, electrics that don't smoke and carbs that actually deliver gas to the engine I painted the tank and tried out some Comstar wheels:

I started by stripping the bike down a bit and repairing the electronics and cleaning the carbs. A previous owner chopped the fuse block out and used wire nuts.

I wired in a factory fuse block from another CB:

Once I got the bike to a rideable state by removing the awful muffler, electrics that don't smoke and carbs that actually deliver gas to the engine I painted the tank and tried out some Comstar wheels:

The bike was at a great state for the summer of 2010 once the qwerks were resolved and I painted the bike and seat cowl.

Subscribe to:

Comments (Atom)